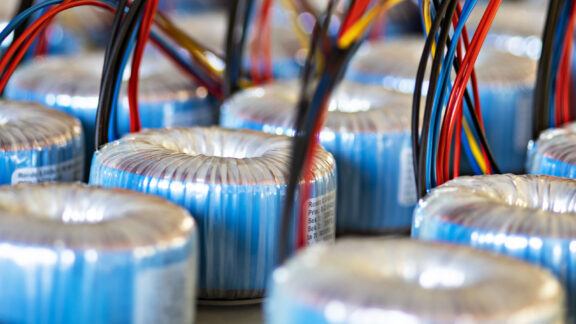

Toroidal transformers

rondo toroidal transformers

Since 1992, Rondo stands for quality “Made in Germany”. We take your specifications for the development and calculation of individual solutions tailored exactly to your requirements. We support you from the production of samples through to series production.

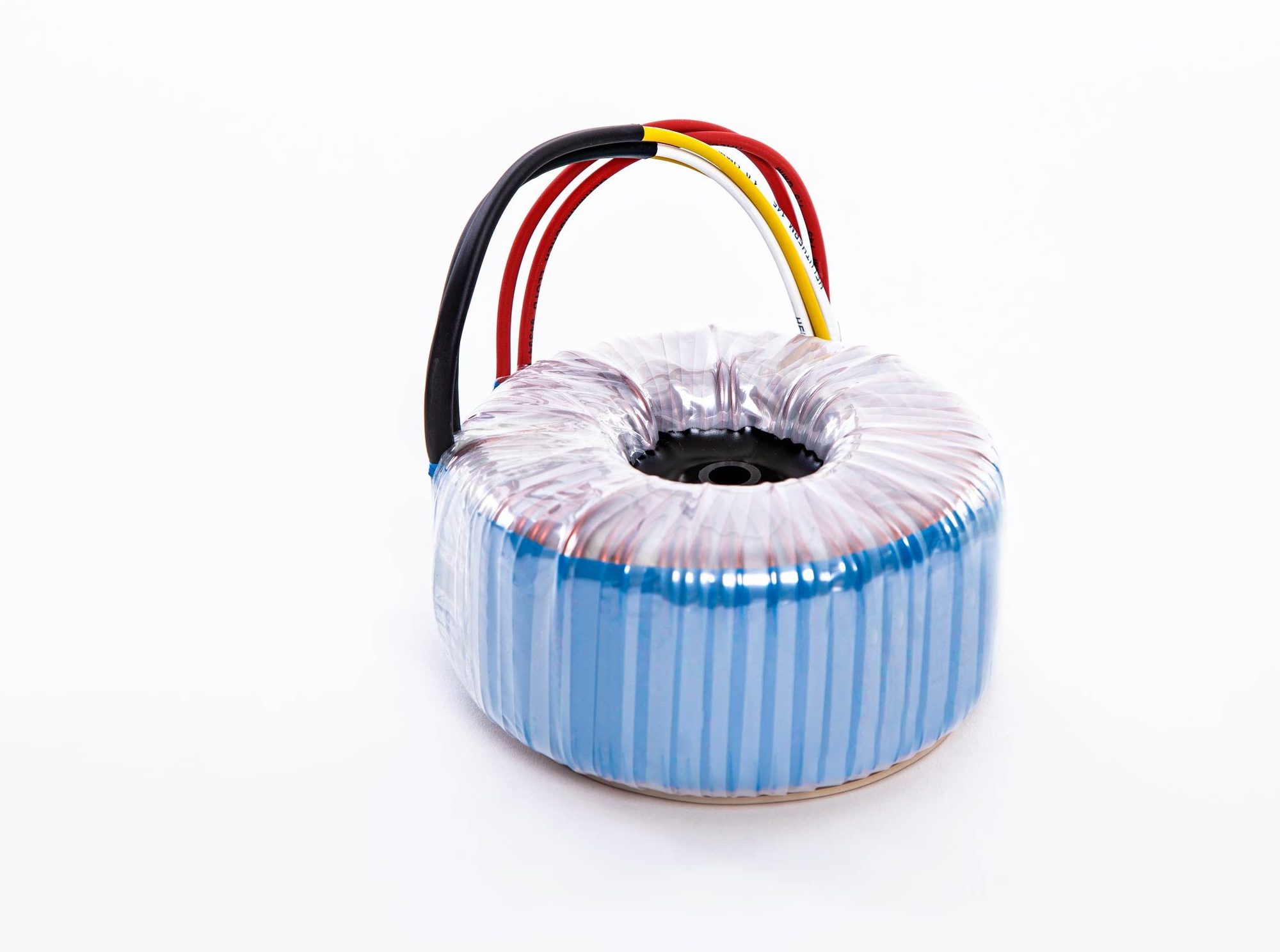

Toroidal transformers have numerous advantages compared with conventional transformers:

- compact design up to 50% lower volume and lower weight

- low-stray magnetic field, in the ratio approx. 1:8 as opposed to conventional transformers

- optimum efficiency level through extremely low iron losses (core material used VM 111-35 P)

- no transformer buzzing

- good temperature behavior through homogeneous distribution of windings over the whole iron core. Average temperature increase of 40 – 50 Kelvin (insulation material used is temperature class E, corresponding to 120°C)

- simple assembly conditions

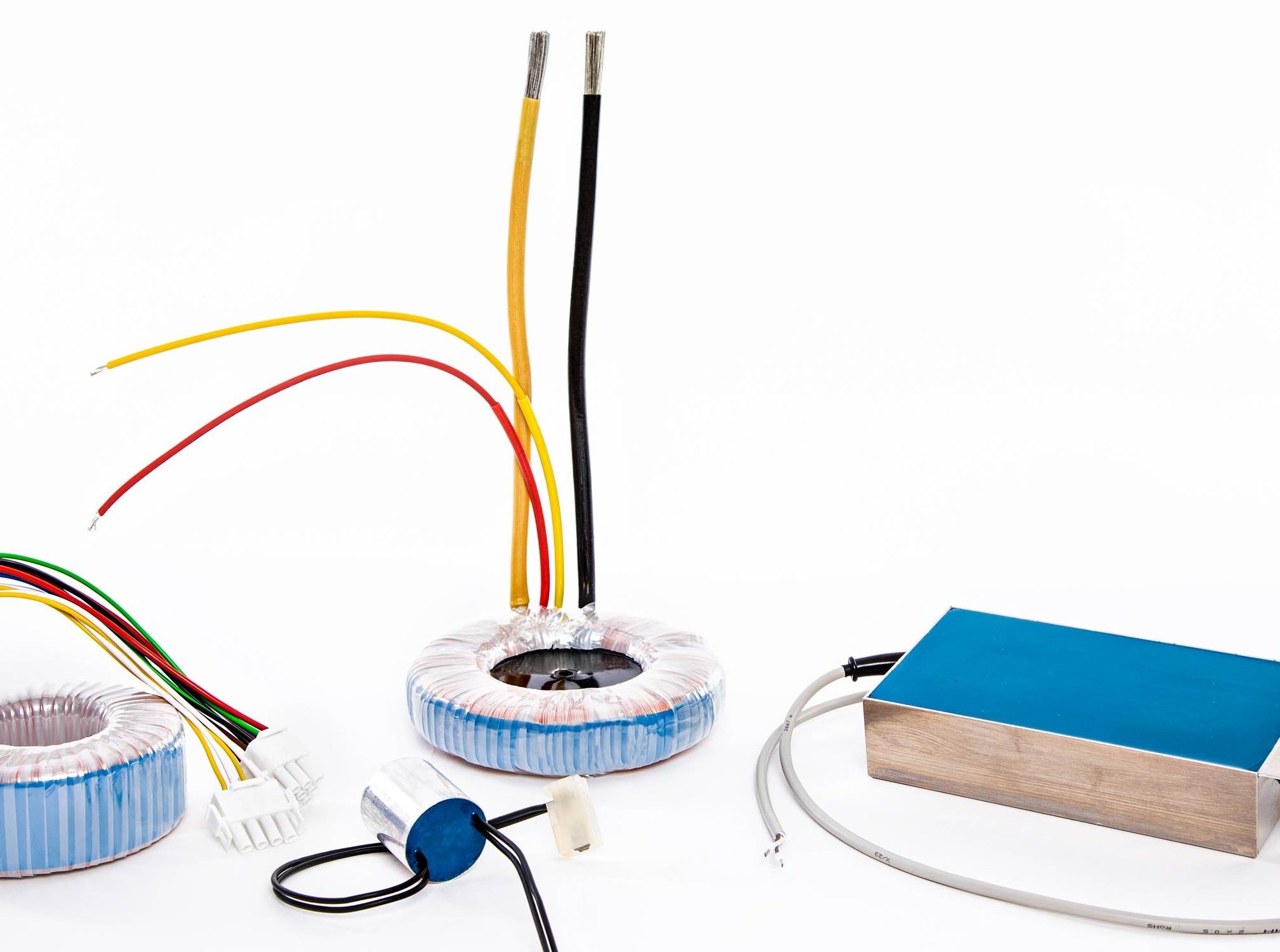

Rated output 1VA-6500VA

Mounting

-mounting set steel

+rubber washer

Rated output 1VA-6500VA

Mounting

-with sleeve

-threaded sleeve

-installation plate

Rated output 1VA-6500VA

Mounting

-in housing

-in housing with printg

Rated output 1VA-6500VA

Model

-customized according to your requirements

Rondo toroidal transformers standard program

Operating conditions:

Standard toroidal transformers are designed for operating frequency of 50 to 60 Hz. The temperature increase at nominal load 40 to 50 Kelvin, at surrounding temperature of 40°C.

Special models:

Other performance and dimensions, additional shielding, temperature safeguards, temperature switches, higher insulation class, connecting and mounting options on request.

Model: open, with covering bandage, T40/E, IP 00, protection class II prepared in compliance with VDE 0570/EN 61558

Test voltage: 5000 V, prim-sec.

Mounting: 1 metal washer / 2 rubber washers hole closure

Connections: free , rigid wire ends 200 mm long

Color code:

primary yellow – yellow

secondary I red – green

secondary II natural – blue

| Power rating

(VA) |

measurements

in mm |

weight (kg) | idle

voltage ncrease |

mounting | |||

|---|---|---|---|---|---|---|---|

| ø | H | total

weight |

copper

weight |

% | metal

washer |

2 rubber

washers |

|

| 20 | 61 | 32 | 0,30 | 0,09 | 18 | 50 | 60 |

| 30 | 74 | 30 | 0,50 | 0,16 | 16 | 50 | 60 |

| 50 | 79 | 37 | 0,70 | 0,23 | 14 | 50 | 60 |

| 75 | 89 | 38 | 1,00 | 0,39 | 11 | 60 | 70 |

| 100 | 93 | 42 | 1,25 | 0,42 | 10 | 70 | 80 |

| 150 | 97 | 51 | 1,75 | 0,72 | 9 | 70 | 80 |

| 200 | 115 | 53 | 2,30 | 0,78 | 7 | 90 | 100 |

| 250 | 118 | 55 | 2,50 | 0,90 | 7 | 90 | 100 |

| 300 | 121 | 63 | 2,65 | 1,23 | 6 | 90 | 100 |

| 400 | 131 | 64 | 3,50 | 1,50 | 6 | 90 | 100 |

| 500 | 143 | 65 | 4,30 | 1,85 | 5 | 110 | 120 |

| 630 | 145 | 77 | 5,10 | 1,89 | 5 | 110 | 120 |

| 800 | 155 | 72 | 5,50 | 2,30 | 4 | 110 | 120 |

| 1000 | 165 | 72 | 6,60 | 2,50 | 3 | 110 | 120 |

| 1200 | 195 | 72 | 7,65 | 3,45 | 3 | 130 | 140 |

| 1600 | 199 | 98 | 9,80 | 3,95 | 3 | 130 | 140 |

| Power rating

(VA) |

voltage (V) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10 | 2×6 | 2×12 | 2×15 | 2×18 | 2×24 | 2×30 | 2×48 | 2×60 | 2×115 | |

| 20 | x | x | x | x | x | |||||

| 30 | x | x | x | x | x | |||||

| 50 | x | x | x | x | ||||||

| 75 | x | x | x | x | x | x | ||||

| 100 | x | x | x | x | x | |||||

| 150 | x | x | x | x | x | |||||

| 200 | x | x | x | |||||||

| 250 | x | x | x | x | ||||||

| 300 | x | x | x | x | ||||||

| 400 | x | x | x | x | ||||||

| 500 | x | x | x | x | ||||||

| 630 | x | x | x | |||||||

| 800 | x | x | x | |||||||

| 1000 | x | x | ||||||||

| 1200 | x | x | ||||||||

| 1600 | x | |||||||||